|

| Walnut Shell Filter |

Everyday the demand on oil producers around the world continues to increase at exponential rates. The only way to keep up with the demand is to increase production, and that means increasing efficiency so that the trip from the field to the pump doesn't sap a company's profits.

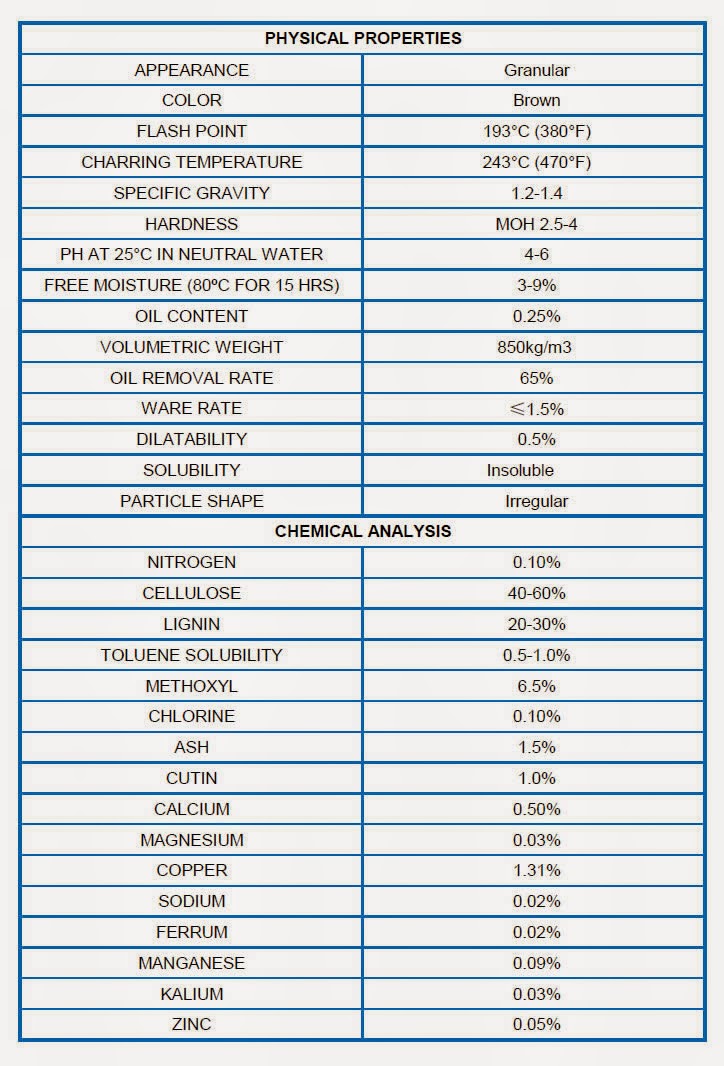

This increased production also means increased waste that needs to be cleaned in accordance with environmental regulations. This is where walnut shells can lend a hand and treat the wastewater that results from oil drilling. This wastewater is filtered through screens containing black walnut shells that remove up to twice as much waste as sand filters.

Furthermore, walnut shell filters can clear three times the amount of waste before they need to be cleaned. This is possible because walnut shells have the ideal surface structure to filter water through, and their resilience to attrition means that they last longer and provide a level of effluency that is unmatched.

Not only do walnut shells make the clean-up easier, they can also be mixed with mud and utilized to resolve circulation and unplug wells in a manner that won't significantly impact the consistency of drilling fluid.

Finally, walnut shells are an ideal blast media for use in pressure cleaning applications at the drill site. They are coarse, but not so hard that they can damage sensitive structures make of fiberglass, wood, or plastic. Plus, since they are not toxic, there is absolutely no risk of silicosis as there is when using silica based blasting media.

Whether being used to filter waste, speed up production, or clean machinery in between drilling cycles, walnut shells are 100% recyclable which means you can use and reuse them many times over. This allows you to not only reduce operating costs, but it's an easy way to help keep the environment cleaner as well.

Utilizing walnut shells in oil drilling is just one of the many applications Flowspec has been helping our clients with since 1981. We invite you to contact us to learn more about the ways we can help your business incorporate walnut shells into your operations.

This increased production also means increased waste that needs to be cleaned in accordance with environmental regulations. This is where walnut shells can lend a hand and treat the wastewater that results from oil drilling. This wastewater is filtered through screens containing black walnut shells that remove up to twice as much waste as sand filters.

Furthermore, walnut shell filters can clear three times the amount of waste before they need to be cleaned. This is possible because walnut shells have the ideal surface structure to filter water through, and their resilience to attrition means that they last longer and provide a level of effluency that is unmatched.

Not only do walnut shells make the clean-up easier, they can also be mixed with mud and utilized to resolve circulation and unplug wells in a manner that won't significantly impact the consistency of drilling fluid.

Finally, walnut shells are an ideal blast media for use in pressure cleaning applications at the drill site. They are coarse, but not so hard that they can damage sensitive structures make of fiberglass, wood, or plastic. Plus, since they are not toxic, there is absolutely no risk of silicosis as there is when using silica based blasting media.

Whether being used to filter waste, speed up production, or clean machinery in between drilling cycles, walnut shells are 100% recyclable which means you can use and reuse them many times over. This allows you to not only reduce operating costs, but it's an easy way to help keep the environment cleaner as well.

Utilizing walnut shells in oil drilling is just one of the many applications Flowspec has been helping our clients with since 1981. We invite you to contact us to learn more about the ways we can help your business incorporate walnut shells into your operations.